The Project:

Dust collection plumbing

The Drink:

Miller Lite

The Pairing:

Nothing like a cheap, lite, American, mass-produced beer to choke down while doing some plumbing. Plumbers butt optional.

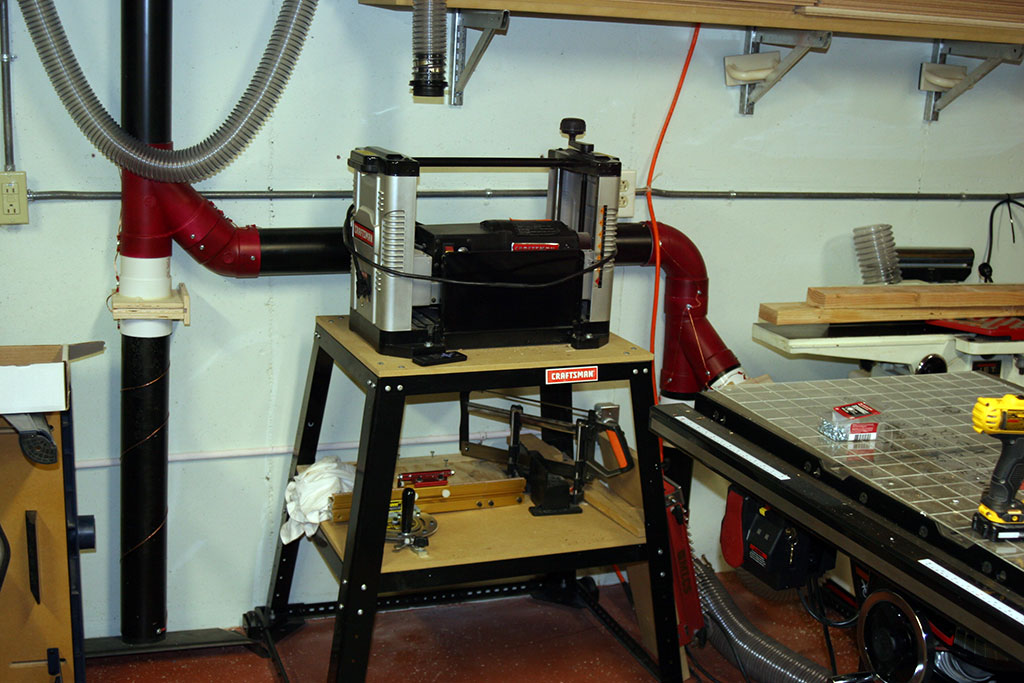

I added a Dust Collection (DC) system to my shop this month. WoodCraft was running a special on their Rikon 2HP DC units with 5-micron filter bag, so I picked on up because I was quite annoyed with moving the shopvac/dust deputy around the shop to every tool. And the whine of the shopvac running for long is enough to drive anyone crazy.

Project

Let's get started. Crack open that miller lite that sucks perhaps even more than the DC itself. Grab your needed tools, some pipe, fittings, spraypaint, and electrical tools because we're going to ground the shit out of these pipes.

I went all out. The DC unit is actually outside my basement shop in the storage area. Less noise for me, right? It's plumbed through the wall, into a wanna-be vortex seperator, then continued to be plumbed throughout the shop. I used 4" Sewer and Drain piping, home-made blast gates, and a variety of pvc-to-flexible-hose connectors to get everything connected. I even took the time to spray paint the PVC so it looks all pretty like. Well for now, until it gets covered in a layer of dust.

Process

Cutting the PVC

Seems you can only find 10ft lengths of pipe at the store. So they need to be cut. I found out that I have no control over a hacksaw when attempting to cut straight through a piece of PVC. Luckily, a quick setup on the table saw with a stopblock on my mitre gauge worked perfectly. Just spin the pipe along the gauge while keeping it's end tight against the stop block and you've got a nice, straight cut. Unfortunately, it makes a ton of PVC chips/dust, which I couldn't suck up because I didn't have the DC installed yet.

Attaching Fittings

For junctions, I used an assortment of 90°, 45°, and 22.5° elbows, and Wyes. I skipped the pvc cement on these joints, thinking it will be easier should I ever need to change things. Also, I have no ventilation in my shop so I probably would have keeled over dead if the Miller Lite didn't do the job already. So I just press-fitted them, and then shot some #8x5/8" sheet metal screws through the joints. They seemed to fit the thickness of the pvc and join perfectly.

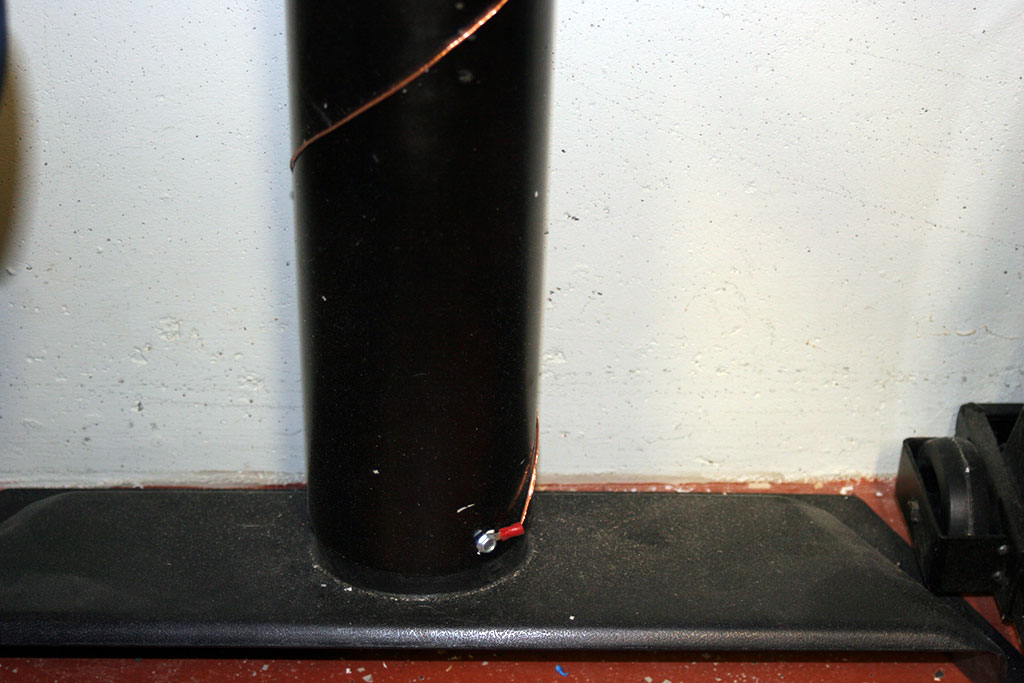

Grounding

Even though mythbuster's busted the whole shop-explosion from static electricity sparking and blowing up your pvc dust collection system, I still felt like the $20 to ground the system was worth it. Got myself some 18guage stranded bare copper wire from Home Depot (since I couldn't find it anywhere else!) and some #8 ring terminals. Tried to have more Miller Lite at this point — still sucked and couldn't finish it.

To ground, I ran the wire on the inside of the long, straight runs. Then I drilled an angled hole at the end to pull the wire out, put a ring terminal on the end and used one of the sheet metal screws to attach it at the joint. Then at the end of the run, I have it grounded to the DC, and to each tool that it's constantly hooked up to. That part actually took longer than I expected, getting the wire pulled and putting in the screws. One of the articles I found mentioned having wire wrapped around the outside of the PVC in addition to running it inside. Perhaps that will be a future project I choke some more Miller down to should the static charge not dissipate quickly or fully enough.

SoundLevels

But what I really wanted to talk about today was noise level. I set up my handy-dandy iPhone with the dB Meter Pro app to measure sound levels in the shop by where I stand mostly: behind the table saw. I took a few readings, listed below.

| Tool | dB Reading |

|---|---|

| None | 45 dB |

| Sawstop | 87 dB |

| ShopVac | 78 dB |

| Dust Collector | 73 dB |

| Sawstop + ShopVac | 88 dB |

| Sawstop + Dust Collector | 87 dB |

Interesting, isn't it? But for the most part, the pitch of the DC is much less annoying than the ShopVac, which means less grumpiness when I'm done building for the night and head upstairs.

Finishing

Now that it's all done, pull up your favorite shop stool (or get some wood together to make one), hit the remote on your dust collector, suck some stuff up, kick back, and suck down some of that award-winning Miller Lite!